Today’s production inkjet technology excels in every way when it comes to the world of print and mail. The newest available devices deliver stunning print quality at breakneck speeds, while features like in-line finishing and real-time personalization push the boundaries of what's possible. Still, this hasn’t always been the case. Inkjet presses had humble beginnings and were once effective for only a handful of applications. While digital technology offered a more efficient alternative to traditional offset, lower print quality and fewer substrate options meant that the inkjet production presses of yesteryear were often purchased for a single purpose or document type.

Thanks to rapid advancements in inkjet technology over the past few years, things have changed. Unfortunately, some print buyers might still be overlooking inkjet based on outdated perceptions, thereby missing out on the advantages it can offer — especially when it comes to direct mail. It’s up to us to reshape outdated impressions that include images of sprayed-on text or muted graphics. This article explores the evolution of production inkjet presses and considers how this remarkable technology can mean better business results for direct mailers.

Early Beginnings

Inkjet technology has been around for decades; in fact, it was developed during the 1950s. Even so, it wasn’t until the late 1970s that inkjet technology was able to be used for printing business documents. Whereas Chester Carlson is credited for the invention of the photocopier, there is no single inventor of inkjet technology. Credit is partly given to a man named John Vaught, who worked for Hewlett-Packard in Silicon Valley. His original inspiration came from a coffee pot.

Recognizing how hot water expands coffee grounds, he wondered if a similar process could heat ink enough to spread it evenly over a sheet of paper. During that same time, a Canon engineer named Ichiro Endo observed the effects when a syringe full of ink accidentally met a soldering iron; the heat caused the ink to increase in volume, which caused it to bubble out in tiny drops. This accident was the driving technology behind Canon’s proprietary Bubble Jet inkjet printers. Though its efforts were impressive, Canon was not acting alone in the development of inkjet. Instead of using heat to expand the ink into droplets, Epson began to power inkjet with electric currents. This technique, known as micro piezo technology, was used to create and place drops of ink on paper. Meanwhile, companies like Kodak and IBM saw the opportunity for high-speed inkjet printers in the billing market and continued to advance the technology behind inkjet printing.

Although inkjet’s promise was increasing, applications were limited to text-heavy documents like statements, manuals, reports, and instructions that contained simple graphics and diagrams with only basic color requirements. Needless to say, the early days of production inkjet were, well, rough. The 1970s and 80s saw clunky behemoth devices with sluggish speeds and inconsistent print quality. Think smeary address blocks and color gradients that resembled abstract art more than marketing materials.

Production inkjet has expanded by leaps and bounds since its early days, thanks to several key technological advancements. Its evolution is a story worth sharing with buyers of direct mail. One of the most notable changes is the advancements in printhead technology that allow for precise droplet placement and control. The results include sharper print quality and higher resolutions. Most inkjet printheads are now designed with more nozzles, which means droplets of ink can be placed with greater accuracy. Another remarkable difference is how many printheads on the market today can adjust the droplet size on the fly. This capability translates to photorealistic images and crisp text that is guaranteed to grab attention and drive engagement.

Innovations in the ink itself are also worth talking about. Today, manufacturers of inkjet presses have learned that the relationship between the ink and the printheads they use can often lead to a competitive advantage. Regardless of whether a press uses solvent-based or water-based ink (which includes both dye and pigment variations), the chemistry of the ink continues to advance, offering a wider color gamut and more vibrant colors. The ink also determines image adhesion and substrate flexibility. Improved ink-drying methods enable faster print speeds without compromising the print quality.

With today’s advanced technologies, matching ink usage to specific paper or substrate types is no longer a manual task. Much like smartphones, the brains of a production inkjet device have access to more data than ever before. A great example is how the press automatically adjusts its ink usage to suit different materials, resulting in better print quality and less trial and error.

Included in the production inkjet value proposition is the ability to meet short print and delivery times without compromising print quality. One of the key influences in that statement is how the press can access data in real-time to improve equipment performance and reduce downtime. Now, with higher speeds and color accuracy, print buyers can print variable data and personalize documents at scale. These capabilities empower businesses to create personalized marketing materials and customized communications that are engaging, efficient, and cost-effective.

Data acts as the invisible conductor, orchestrating every step of the printing process to deliver continuous improvement. Machine learning means a steady rhythm of press performance and efficiency. This dynamic optimization squeezes out the most value from each print run, maximizing productivity and reducing costs.

It was only effective for a limited number of uses in the past, but inkjet technology has since made significant advancements in a remarkably short amount of time. Improved ink chemistry, printhead architecture, and ink drying performance have made inkjet a viable option for a much broader range of applications, including those preferred by luxury brands. Page volumes produced on inkjet continue to rise as work is transferred from offset to inkjet.

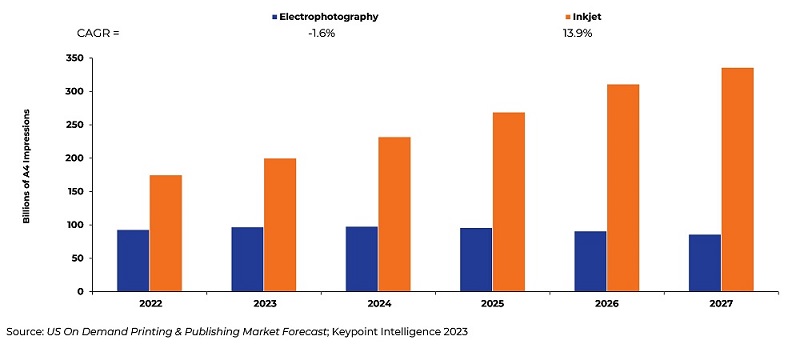

Additional page growth is found with applications that won’t fit well on a traditional press yet still require high-quality images. Such work was previously designated to electrophotographic (EP) or toner-based production presses. By building on previous technologies, inkjet continues to see incredible productivity, flexibility, and quality improvements. Data from Keypoint Intelligence supports a promising future, with color inkjet outpacing EP page volume by leaps and bounds over the next several years.

Figure 1: Color Print Volumes – Electrophotography vs. Inkjet

The evolution of this amazing technology opens the door to new growth with applications like catalogs, magazines, and photo products.

Production inkjet has evolved into a direct mail powerhouse, delivering stunning images and razor-sharp text at previously unheard-of speeds. As research and development continues, we can expect even more innovations that push the boundaries of what we can print and how we print it.

Evolving from its slow, splotchy beginnings to a versatile, high-flying force, production inkjet has transformed the print and mail industry. Its journey is a testament to human ingenuity and a glimpse into a future where every printed piece is a masterpiece of personalization and possibility.

Karen Kimerer of Keypoint Intelligence has experienced the many challenges of expanding current market opportunities and securing new business. She has developed a systematic approach to these opportunities, addressing the unique requirements of becoming a leader in our changing industry. She is well-versed in 1:1 marketing, web-to-print, direct mail, book publishing, supply chain management, data segmentation, channel integration, and photo products.

This article originally appeared in the January/February, 2024 issue of Mailing Systems Technology.